Purdue University and the White River Alliance brought together experts to tackle one of Indiana’s most pressing challenges: how to balance industrial water demands with protecting the environment and how wastewater reuse can be vital to that mission.

As industries expand and water resources face increasing strain, the conversation around sustainable solutions is urgent. Experts discussed the promise of water reuse as a way to reduce environmental impact while supporting industrial growth.

Ernest R. Blatchley III, professor of environmental engineering at Purdue University, introduced wastewater reuse during the forum. According to Blatchley, current wastewater practices that are effective at removing pollutants were developed a century ago, when electrical consumption was not a research focus. “Generally (the processes) were developed with minimal attention paid to resource recovery, which suggests there are opportunities for improvements,” Blatchley said.

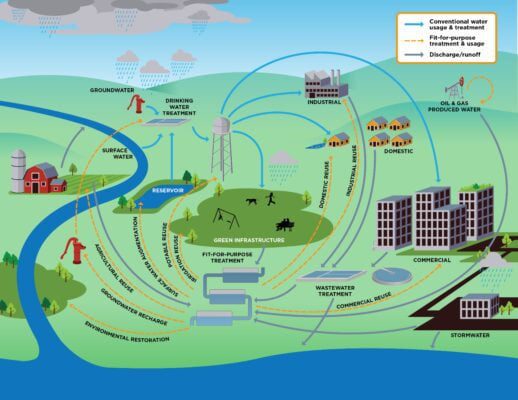

A forward-looking wastewater management solution focuses on resource and water recovery and reuse.

“It is possible to develop these systems so that they are net positive in terms of energy rather than net negative,” Blatchley said.

Water reuse is not practiced everywhere, however. Florida, California, Texas and Arizona are responsible for more than 80% of water reuse. Indiana is one of only a few midwestern states that have water reuse regulations or guidelines for agriculture.

The demand for water reuse is highest in water-starved areas, which have increased due to climate change.

Prakash Rao, department head of building and industrial applications for the Lawrence Berkley National Laboratory, discussed the applications for water reuse on the industrial scale, namely the efficiency opportunities.

Manufacturing water use constitutes approximately 6% of all water use in the U.S., with the top sectors being paper primary metals, chemicals, refining and food, according to the U.S. Geological Survey from 2015. That 6% represents 19.7 billion gallons of water per day.

Indiana is the number one user in manufacturing water use, with Lake County utilizing the most. With nearly 2.5 billion gallons per day being used, the question of water reuse is at the forefront of environmentalists’ minds.

Water scarcity is also directly related to manufacturing industries. Places where metals, equipment, petroleum and other products are manufactured are more likely to be water scarce, leading experts to wonder how water reuse could play a role in replenishing the resource.

“Some of the more complex (reuse) opportunities may not be so complex when you think about what they’re doing and the systems they handle,” Rao said.

Nichole B. Morris, global water resources and environmental leader for Cummins Inc., spoke about Cummins’ sustainability goals and their shift in focus to water use versus energy.

“We started metering and understanding where our water use is coming from and our balances across our facilities and we noticed that we had a lot of easy things we could do,” Morris said.

In 2030, Cummins has several sustainability goals to reduce emissions, generate less water, recycle packing and plastics and produce net water benefits in all regions.

“We provide more water globally than we use globally,” Morris said.

Cummins is an industrial company who has taken steps to reduce, reuse and recycle water. A staple in Indiana’s economic sector, Cummins brings to light the steps Hoosier companies can take to protect the environment.

Eric Rosenblum, CEO of Envirospectives Inc., provided perspectives, incentives and tools for sustainable industrial water use. The costs and barriers can play a big role in companies not reusing water.

Collaboration among stakeholders is a must, according to Rosenblum, and every company has different incentives and barriers to sustainable water practices.

Heather Tugaoen, process engineer for Stantec, spoke about the policy side of industrial water reuse and the next steps forward. The business case for water reuse, she argues, is providing water security, reducing infrastructure cost, supporting sustainability goals and supporting environmental compliance.

“Cumulatively by the 2030s we’re looking at significant sums of money that can be saved and reinvested elsewhere if we’re starting to use municipal and industrial reuse across the midwestern region,” Tugaoen said.

For more information about Purdue and White River Alliance’s Science and Policy Forums, visit thewhiteriveralliance.org.

To read more local news, click here.

Contact Health & Environmental Reporter Hanna Rauworth at 317-762-7854 or follow her on Instagram at @hanna.rauworth.

Hanna Rauworth is the Health & Environmental Reporter for the Indianapolis Recorder Newspaper, where she covers topics at the intersection of public health, environmental issues, and community impact. With a commitment to storytelling that informs and empowers, she strives to highlight the challenges and solutions shaping the well-being of Indianapolis residents.